News center

Company News

Share the latest information

How is the elevator decorative sheet produced?

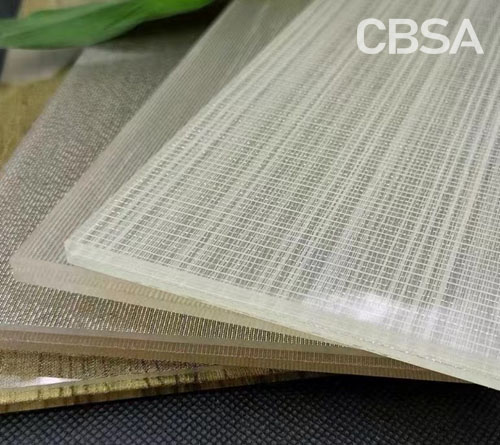

Elevator decorative sheet has already accounted for an important element of elevator car decoration. It has very high requirements on the surface of stainless steel decorative sheet. Let's break down how the elevator decorative sheet is produced.

The color stainless steel decorative sheet is a colorless stainless steel coil processed into a flat plate after the required custom size, that is, the size of 1219*2438 or 1219*3050MM, because this size meets the needs of later processing, 1219 is the width size, and it is also the processing equipment The maximum width size is now, so the colorful decorative sheets that everyone buys are all these sizes. The surface of the plate is frosted to make the surface smoother and easier for subsequent processing. The next step is to process the stainless steel surface with corresponding processes, such as mirror, wire drawing, etching, printing and other processes in order to achieve the products we need.

As for the processing process of etching the elevator decorative sheet, we will give you a detailed introduction. First, after the flat plate-after the surface is frosted-if a mirror effect is required, then the surface is polished by 8K, and it is It needs to be polished several times to show the effect of a mirror--------then the surface is printed to achieve the designed pattern effect. After the printing is etching, the chemical principle is used to corrode part of the stainless steel surface. This process Shallow or deep etching can be performed according to needs. Shallow etching only has a hand-feel effect, and the surface is not obvious. Deep-etching looks obvious and feels comfortable. This is customized according to the requirements of use, and the price of deep-etching will be more expensive. The cost will be higher. --------After the etching, if you need to paint, go to the electroplating link for reprocessing. The electroplating adopts PVD coating vacuum plating. This process has good quality, durability and is not easy to damage the surface, which increases the service life. effect.

After the processing is completed, a laser protective film needs to be used to protect the surface to prevent scratches on the surface of the product and affect the use effect. Finally, the packing is carried out, and export packing boxes are generally used to protect the safety of the product during transportation.

Well, to learn more about colored stainless steel sheet and processed products, please check the relevant column of CBSA International.

The color stainless steel decorative sheet is a colorless stainless steel coil processed into a flat plate after the required custom size, that is, the size of 1219*2438 or 1219*3050MM, because this size meets the needs of later processing, 1219 is the width size, and it is also the processing equipment The maximum width size is now, so the colorful decorative sheets that everyone buys are all these sizes. The surface of the plate is frosted to make the surface smoother and easier for subsequent processing. The next step is to process the stainless steel surface with corresponding processes, such as mirror, wire drawing, etching, printing and other processes in order to achieve the products we need.

As for the processing process of etching the elevator decorative sheet, we will give you a detailed introduction. First, after the flat plate-after the surface is frosted-if a mirror effect is required, then the surface is polished by 8K, and it is It needs to be polished several times to show the effect of a mirror--------then the surface is printed to achieve the designed pattern effect. After the printing is etching, the chemical principle is used to corrode part of the stainless steel surface. This process Shallow or deep etching can be performed according to needs. Shallow etching only has a hand-feel effect, and the surface is not obvious. Deep-etching looks obvious and feels comfortable. This is customized according to the requirements of use, and the price of deep-etching will be more expensive. The cost will be higher. --------After the etching, if you need to paint, go to the electroplating link for reprocessing. The electroplating adopts PVD coating vacuum plating. This process has good quality, durability and is not easy to damage the surface, which increases the service life. effect.

After the processing is completed, a laser protective film needs to be used to protect the surface to prevent scratches on the surface of the product and affect the use effect. Finally, the packing is carried out, and export packing boxes are generally used to protect the safety of the product during transportation.

Well, to learn more about colored stainless steel sheet and processed products, please check the relevant column of CBSA International.

Article tags: How is the elevator decorative sheet produced?

Contact Us

Add:

No. 5, 2st Road,

Road, Tancun Industrial Zone, Chencun Town,

Shunde District, Foshan City,China

Phone/whatsApp: 008613925936221

wechat: fs1234tk

Engaged in color stainless steel research and development, production and processing for 12 years, with professional technical experience. Product output is used in various countries and regions around the world.