News center

Company News

Share the latest information

Is spot welding or full welding used for stainless steel furniture

In recent years, stainless steel furniture has been deeply loved by everyone. Not only does it have a high appearance, but also has a very good temperament. The decorative effect is very good. This is its charm.

Regarding the custom processing procedures of colored stainless steel furniture, I believe that everyone is more empathetic, or even not familiar with it. Yes, stainless steel furniture is a processing problem. It is inconvenient to consider the difficulty of material processing, but also to understand the processing performance and processing sequence. This also determines the final effect and quality of the product.

For furniture processing, the first is the design drawings, and then the furniture structure. These two aspects are clarified. Then, we will make it and find a better method for processing. When processing, we need to consider spot welding or full welding. What is the difference between them, let's take a look together below.

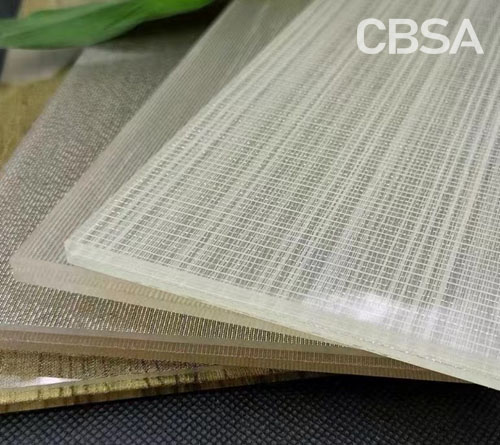

Spot welding is to leave the seam processing, and the appearance looks like there are spliced fine seams. When we need to be firm, we only need to perform hidden spot welding in key parts and places that do not affect the appearance of the product to achieve a firm effect. This method is suitable for color material processing, and the products produced will be more exquisite and beautiful, but it needs to test the skill and craftsmanship of the technicians. This is a very high technical difficulty, and the difficulty lies in the design, technical operation, and processing implementation before production.

Full welding, that is, all splicing positions need to be fully welded, and need to be polished to meet the design requirements. This method is not too difficult. First of all, it uses ordinary unprocessed stainless steel materials to conduct structural splicing and welding firmly, and then manual polishing, and then PVD coloring, and finally achieve the desired effect. All of these processes are completed by hand, and the products are beautiful when they are made by hand, and the products are hard to accept with poor handwork. This is technical work. Because manual craftsmanship varies from person to person, and mass production cannot control the perfect effect, only mechanized production can do better. The appearance effect of the above spot welded products is completed mechanically before processing, so the quality is better than that of fully welded products.

For special-shaped products, it can only be produced by the full candle process, which must be completed by various manual processing methods. Only flat products can be spliced by spot welding using processed materials. If you want to know the specific production operation, you can check the video content of the CBSA International official website. There are many video introductions of various production processes, which can help you understand and design your personalized stainless steel furniture products.

Well, welcome to pay attention to CBSA International and learn more about stainless steel products.

Regarding the custom processing procedures of colored stainless steel furniture, I believe that everyone is more empathetic, or even not familiar with it. Yes, stainless steel furniture is a processing problem. It is inconvenient to consider the difficulty of material processing, but also to understand the processing performance and processing sequence. This also determines the final effect and quality of the product.

For furniture processing, the first is the design drawings, and then the furniture structure. These two aspects are clarified. Then, we will make it and find a better method for processing. When processing, we need to consider spot welding or full welding. What is the difference between them, let's take a look together below.

Spot welding is to leave the seam processing, and the appearance looks like there are spliced fine seams. When we need to be firm, we only need to perform hidden spot welding in key parts and places that do not affect the appearance of the product to achieve a firm effect. This method is suitable for color material processing, and the products produced will be more exquisite and beautiful, but it needs to test the skill and craftsmanship of the technicians. This is a very high technical difficulty, and the difficulty lies in the design, technical operation, and processing implementation before production.

Full welding, that is, all splicing positions need to be fully welded, and need to be polished to meet the design requirements. This method is not too difficult. First of all, it uses ordinary unprocessed stainless steel materials to conduct structural splicing and welding firmly, and then manual polishing, and then PVD coloring, and finally achieve the desired effect. All of these processes are completed by hand, and the products are beautiful when they are made by hand, and the products are hard to accept with poor handwork. This is technical work. Because manual craftsmanship varies from person to person, and mass production cannot control the perfect effect, only mechanized production can do better. The appearance effect of the above spot welded products is completed mechanically before processing, so the quality is better than that of fully welded products.

For special-shaped products, it can only be produced by the full candle process, which must be completed by various manual processing methods. Only flat products can be spliced by spot welding using processed materials. If you want to know the specific production operation, you can check the video content of the CBSA International official website. There are many video introductions of various production processes, which can help you understand and design your personalized stainless steel furniture products.

Well, welcome to pay attention to CBSA International and learn more about stainless steel products.

Article tags: Is spot welding or full welding used for stainless steel furniture

Contact Us

Add:

No. 5, 2st Road,

Road, Tancun Industrial Zone, Chencun Town,

Shunde District, Foshan City,China

Phone/whatsApp: 008613925936221

wechat: fs1234tk

Engaged in color stainless steel research and development, production and processing for 12 years, with professional technical experience. Product output is used in various countries and regions around the world.